These not only increase the quality of our products, they also minimize the need for post-processing and speed up the manufacturing process.

That’s why we use the TruPunch 3000 universal machine from TRUMPF for punching, forming, thread cutting and deburring. This not only allows us to efficiently combine several processes, but also offers exceptionally high quality.

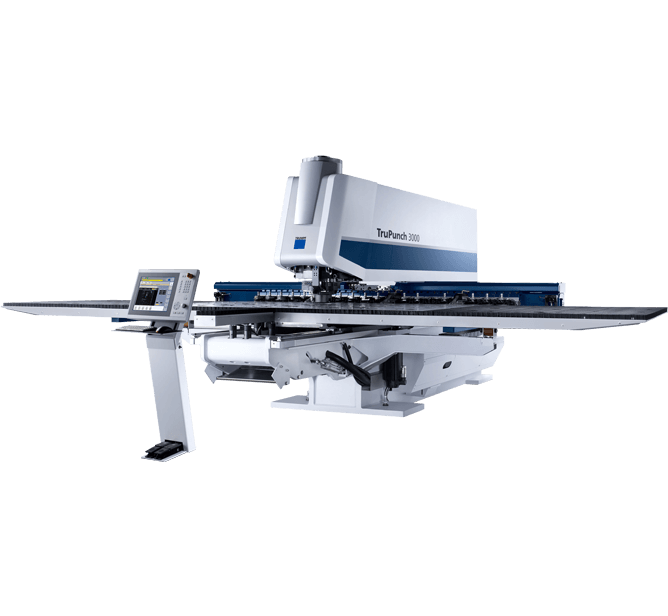

TruPunch 3000 – universal machine

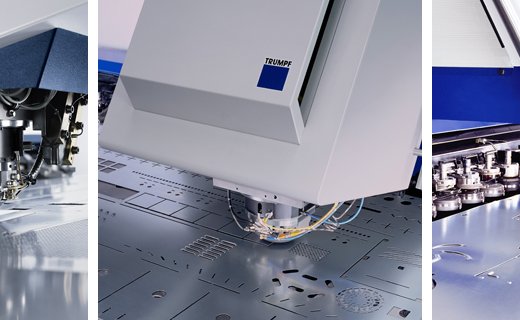

The TruPunch 3000 is the punching machine that can do it all. It not only punches holes in sheet metal, but can also form, bend, form threads, emboss and deburr. It is therefore also well suited for highly complex parts. Various tools can be used to perform all possible operations largely automatically.

The machine is also very user-friendly thanks to the simple digital touchpoint HMI. Finished parts can be sorted automatically, and the machine can be loaded and unloaded automatically. This simplifies the work process for the operator and reduces potential sources of error due to human action.

Advantages of TRUMP punching equipment

- Integrated straightening – deformations that occur during the punching process are compensated automatically

- High processing flexibility – the machine can process many different types of materials in various sizes and thicknesses

- All in one – The machine can combine many different operations, e.g. forming and threading, with punching.

- Automated part handling – Infeed, outfeed and sorting of parts can be automated

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz