PROSTOR-design s.r.o. offers comprehensive services in the field of CNC sheet metal processing. Our own powder coating plant is equal in quality and price to the offer of a specialized powder coating plant. In addition to sheet metal fabrication services, we also undertake electrical installation and assembly of the complete product to ensure that we are able to cover the standard range of customer requirements.

We offer complete machine and plant development followed by sheet metal product design and CNC manufacturing. Our portfolio also includes reengineering of current products. Sheet metal products such as switchboard, electrical switchboard, IT cabinet, rack cabinet, industrial cabinet or other sheet metal enclosures are our main production focus of CNC sheet metal fabrication.

Machine and equipment development, sheet metal parts design and reengineering is a superior service that foreign companies are increasingly interested in. Our biggest advantage is that our own development and design is adapted to our technological capabilities as much as possible, therefore we always keep not only the quality but also a very good price.

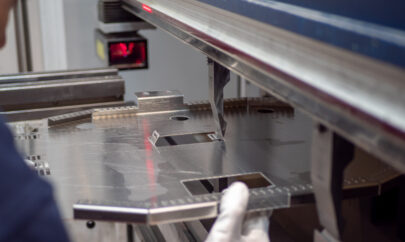

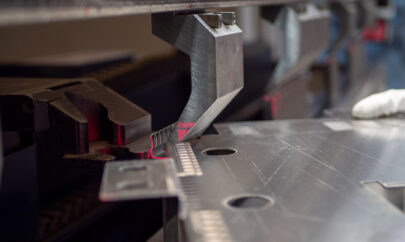

In our CNC sheet metal processing operation we offer sheet metal punching, sheet metal punching and sheet metal bending capabilities on TRUMPF machines, sheet metal bending is performed by a bending press again from TRUMPF. Welding of sheet metal using MIG / MAG and WIG / TIG according to EN 287-1 is a standard in our company, as well as spot welding of sheet metal and resistance welding. Intermediate technologies we offer welding of bolts, bolts and nuts, pressing of bolts and nuts into sheet metal, riveting, threading etc..

The powder coating plant is equipped with WAGNER equipment, which guarantees a high requirement for surface quality. In the pre-treatment we use a product from Henkel, which degreases the product, but at the same time protects the surface of the product against corrosion – phosphating.

The production of cable harnesses, the mounting and rewiring of switchboards and the assembly significantly complements our offer on the market. Thanks to these workplaces, the products leave us completely assembled, fitted or packaged according to the customer’s requirements, who then dispatches the goods directly to the end consumer.

We are a modern European company and our goal is to find solutions for your personal and corporate success.

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz