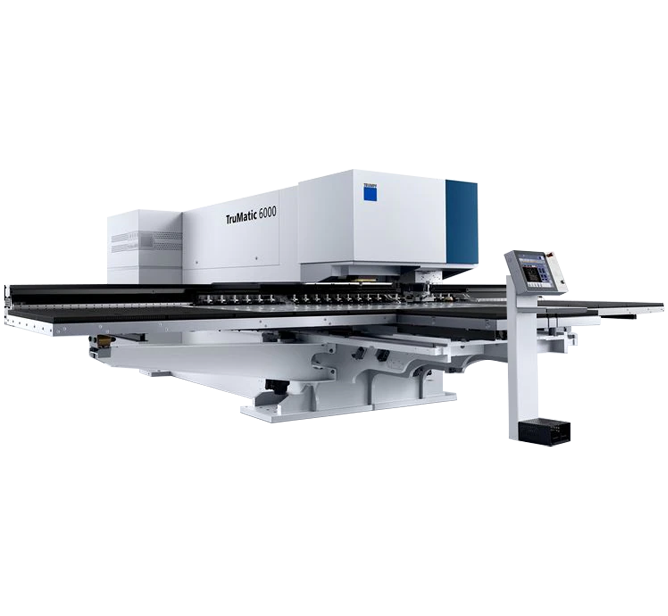

To provide our customers with the best products at the best price, we use the best tools available in our industry.

The precise beam of our TruFlow CO2 laser guarantees sharp edges, enabling reliable high-quality production of more complex parts. The slim laser head can also cut right next to, or even through, existing deformations. This makes it possible to reliably and flexibly produce even unusual or filigree shapes.

At the same time, the lowerable die with beam guidance guarantees scratch-free parts during punching. Various types of material with different thicknesses can also all be processed here with the same punching head without any problems. This optimizes the manufacturing process by saving the time and effort normally required to replace the punching head.

Advantages of TruMatic 6000

- Simultaneous punching and laser cutting

- Scratch-free punching

- Complete processing of the part (often no post-processing required)

- Time-efficient and smooth production thanks to the lowerable die

- High-quality edges with the TruFlow CO2 laser

- Laser quality enables cutting even on existing formations

- Fast and uncomplicated processing

+420 388 314 321

+420 388 314 321  obchod@prostor-design.cz

obchod@prostor-design.cz